Techik Metal Detector for Tablets in Pharmacy

Thechik® — MAKE LIFE SECURE AND QUALITY

Techik Metal Detector for Tablets in Pharmacy

Techik Ultra-High-Definition Intelligent Belt Visual Color Sorter is a versatile solution designed to sort an extensive range of products, including frozen vegetables, fresh and dried fruits and vegetables, dehydrated shallots and garlic, carrots, peanuts, tea leaves, and peppers. Beyond traditional AI-based color and shape sorting, this advanced sorter effectively replaces manual inspection by detecting minor foreign contaminants, such as hair, feathers, strings, and insect fragments, with remarkable accuracy, ensuring high sorting rates, high output, and minimal raw material waste.

Optimized for dynamic and complex processing environments, Techik Ultra-High-Definition Intelligent Belt Visual Color Sorter features an IP65 protection rating and is engineered for stringent hygiene standards, making it suitable for various sorting needs. These include fresh, frozen, and freeze-dried fruit and vegetable products, as well as processing stages in food preparation, frying, and baking. Its multispectral detection capabilities cover color, shape, appearance, and material composition, ensuring comprehensive quality control across all aspects of production.

Equipped with an ultra-high-definition camera, the optical sorter can achieve precise identification of tiny impurities like hair and strings. The proprietary AI algorithm and high-speed rejection system deliver high cleanliness, low carry-out rates, and substantial throughput.

With its IP65-rated protection, this color sorter operates effectively in high-moisture and dusty environments, adapting seamlessly to diverse sorting applications in frying, baking, and more. Designed for easy maintenance, it includes a quick-disassembly structure that simplifies cleaning, ensuring a consistently sanitary production process.

Applications

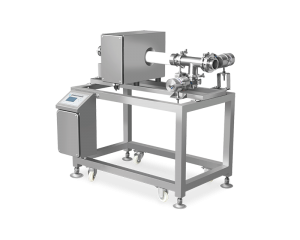

Techik’s Metal Detector for Tablets is designed for the pharmaceutical industry, ensuring that pharmaceutical tablets are free from harmful metal contaminants. The detector is ideal for applications in:

Pharmaceutical Tablets:

Detects metal contamination in tablets used for human health applications, ensuring that products are safe for consumer use.

Nutritional Supplements:

Ideal for the production of dietary supplements and vitamin tablets, ensuring metal-free products.

Herbal Tablets:

Used for detecting metal contaminants in herbal-based tablets, where safety and purity are essential for consumer health.

OTC (Over-the-Counter) Medications:

Ensures that OTC tablet medications, which may be distributed widely, are free from metallic contaminants during production.

Tablet and Capsule Manufacturing:

Works across a range of tablet and capsule formulations in both solid and semi-solid forms, ensuring that all tablets are checked for metal particles.

Features

High Sensitivity Detection:

Capable of detecting even the smallest metal particles, including ferrous, non-ferrous, and stainless steel contaminants, ensuring the safety of pharmaceutical tablet products.

Automatic Rejection System:

Integrated automatic rejection system ensures that any contaminated tablets are immediately removed from the production line, preventing them from reaching packaging or distribution.

Fast and Reliable Performance:

Provides rapid detection with minimal delay, maintaining the flow of production while ensuring thorough inspection of each batch of tablets.

Advanced Multi-Spectrum Technology:

Utilizes multi-spectrum technology to improve sensitivity and reduce the likelihood of false positives, offering enhanced performance for a wide range of tablet types.

Durable and Hygienic Design:

Designed with pharmaceutical-grade stainless steel and materials that are resistant to corrosion and easy to clean, making it ideal for the demanding conditions of pharmaceutical production.

Easy Integration:

Can be easily integrated into existing tablet production lines without requiring significant modifications, ensuring smooth operation and minimal downtime.

Global Compliance:

Meets international standards and regulations such as GMP (Good Manufacturing Practice), HACCP, and FDA, ensuring that pharmaceutical manufacturers comply with the highest industry requirements.

Technical Advantages

High Precision and Sensitivity:

Utilizes advanced multi-spectrum technology to offer exceptional sensitivity, ensuring even the smallest metal particles are detected and rejected, providing precise and reliable detection.

Automatic Rejection Mechanism:

Once a contaminated tablet is detected, it is immediately removed from the production line, preventing defective products from reaching packaging and ensuring quality assurance.

Customizable Detection Parameters:

Operators can easily adjust detection sensitivity levels and operational parameters based on the type of tablet being processed, allowing for a customized solution for different tablet formulations.

Integration with Production Lines:

Techik's metal detectors are designed for seamless integration into existing tablet manufacturing lines, reducing the need for substantial modifications and ensuring minimal disruption to production processes.

Built for Pharmaceutical Environments:

Constructed using pharmaceutical-grade stainless steel, these detectors are built to withstand the high sanitation standards required in pharmaceutical environments while being easy to clean and maintain.

| MODEL | IMD | ||

| Specifications | 50R | 75R | |

| Tube Inner Diameter | Φ50mm | Φ75mm | |

| Sensitivity | Fe | Φ0.3mm | |

| SUS304 | Φ0.5mm | ||

| Display Mode | TFT Touch Screen | ||

| Operation Mode | Touch Input | ||

| Product Storage Quantity | 100 Kinds | ||

| Channel Material | Food Grade Plexiglass | ||

| Rejecter Mode | Automatic Rejecter | ||

| Power Supply | AC220V (Optional) | ||

| Main Material | SUS304 (Product Contact Parts: SUS316) | ||

| Pressure Requirement | ≥0.5Mpa | ||

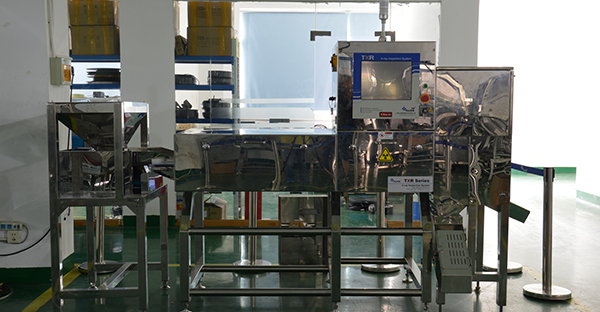

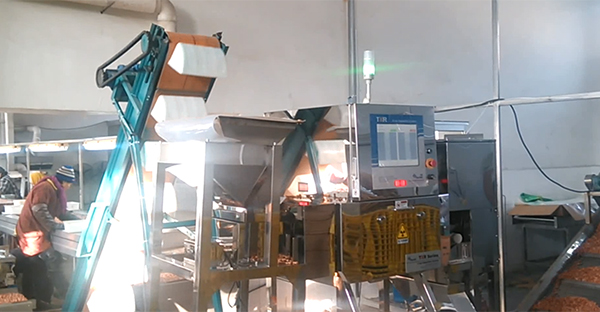

Factory Tour

Packing

Our Goal Is To Ensure Safe With Thechik®.

The software inside Techik Dual-energy X-ray Equipment for Bone Fragment automatically compares the high and low energy images, and analyzes, through the hierarchical algorithm, whether there are atomic number differences, and detects the foreign bodies of different components to increase the detection rate of debris.