Sesebelisoa sa tlhahlobo sa X-ray bakeng sa ho tsitsipana le ho qhekella le oli

Thechik® - etsa bophelo bo sireletsehileng le boleng

Sesebelisoa sa tlhahlobo sa X-ray bakeng sa ho tsitsipana le ho qhekella le oli

Indasteri ea lijo e bobebe e tobana le mathata a maholo ka ho sebetsana le litekanyetso, hangata e bakang bothata ba tšilafalo le spogage. Ho sebetsana le mathata ana a phehellang, mahlale a tlisa sistimi ea eona ea X-ray bakeng sa ho tiisa litho tse fapaneng, ho kenyelletsa le foil e fapaneng, mekotla ea polasetiki, le lipakete tse thibetsoeng.

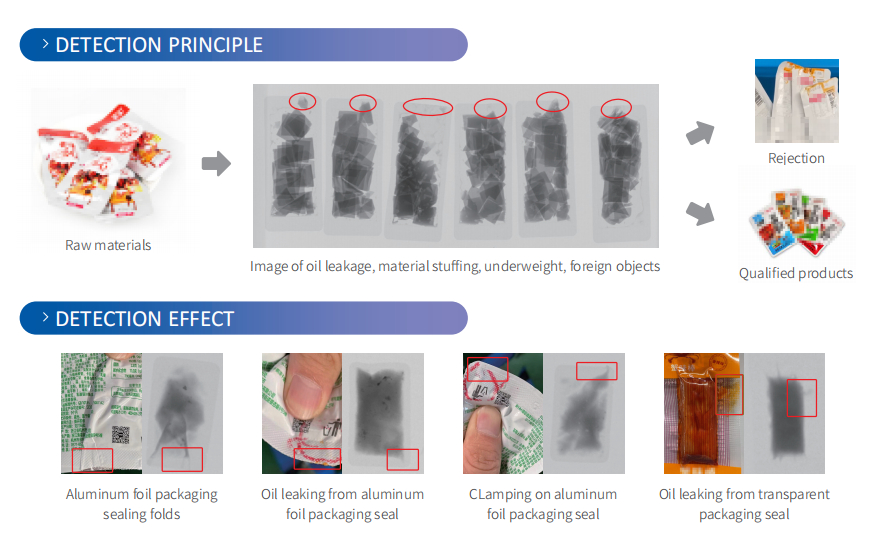

Ho nahana ka monahano o tiileng oa X-ray, ho khetholla ntho e sa tloaelehang ts'ebetsong ea ho tiisa, eo ka ho fetisisa e lebisa ho oli e kopaneng. Bokhoni ba eona bo bohlale bo fana ka pono ea nako ea 'nete le hanghang ho sekisetsa hang-hang, ka ho etsa joalo ba fokotsa monyetla oa tšilafalo le ho ntlafatsa bophelo ba lihlahisoa tsa lihlahisoa tsa lihlahisoa tsa lihlahisoa tsa lihlahisoa. Tlhahlobo ea X-ray ea tlhahlobo e hlahlojoang e hlahlojoa ka botlalo 'me e hlahlojoa botsitso ea thepa ea ho paka, e boloka boemo ba polokeho le katleho ea lijo tse shck. Ka ho sebetsana le mathata a mantlha a ho sesa, ho tiisa le ho tlosoa, tsamaiso ea mahlale e emela sesebelisoa sa boleng bo botle le ts'ebetso ea ts'ebetso.

Video

Likopo

X-rayTlhahloboSistimibakeng saPackage Ho qotsa, ho loha le oli e lutlaE ntlafalitsoe ke Mahlakedi ba fumana ts'ebeliso e pharalletseng khoeng e fapaneng e itšetlehileng ka ho paka le taolo ea boleng. Liindasteri tse ling tsa senotlolo moo mochine ona o sebelisoang hangata ho kenyeletsoa:

Indasteri ea lijo le tse tsoekere: TheX-rayTsamaiso ea tlhahlobo e bapala karolo ea bohlokoa ea ho netefatsa botšepehi ba ho paka libakeng le lefapheng la ho tsoekere. E thusa ho totobala lintho tsa basele, tse kang likotoana tsa tšepe kapa lithi-pele, le tsona li ntse li khetholla litaba tse amanang le ho tiisa lintho tse fapaneng tsa thepa ea ho paka.

Liiporitiwa tsa pharmaceutical: Ho etsa lintho tsa meriana, ho boloka boleng le polokeho ea lihlahisoa tse behiloeng ho bohlokoa haholo. TheX-rayTlhahlobo ea tlhahlobo ho netefatsa bonnete ba ho sebelisa lithethefatsi, ho bona hore na ho sa tsotellehe ho tsitsipana ha lithethefatsi, ho tseba hore na melaoana ea Liindasteri ea indasteri.

Li-cosmetics le indasteri ea tlhokomelo ea botho: Litseiti le lihlahisoa tsa tlhokomelo ea motho li hloka ho paka e tšepahalang ho boloka boleng ba bona le ho qoba tšilafalo. TheX-raySistimi ea tlhahlobo e thusa ho khetholla litaba tse amanang le ho tiisa bots'epehi, netefatsa hore lihlahisoa lia kopana

Ka kakaretso, theX-raySistimi ea tlhahlobo e na le lits'ebeliso tse fapaneng tsa likopa-hloko moo ho bohlokoa hore boleng le botsepehi ba polokeho, le khotsofalo ea bareki.

Monyetla

Ho lemoha ha litšila

Lintjoanano: tšepe, khalase, majoe le litšila tse ling tse bohloko; Likhele tsa polasetiki, seretse, maqhubu a cable le litšabo tse ling tse tlase tse tlase.

Oli e lutlang & e anyehang

Ho hana ka nepo bakeng sa ho lutla hoa oli, ho loma litšila, jj.

Inthaneteng ea marang-rang

Ketso ea tlhahlobo ea ntoa.

Ho lekola boima ba 'mele,±Palo ea 2% ea tlhahlobo.

Ho nona haholo, ho ba tlase, mokotla o se nang letho. jj. e ka hlahlojoa.

Tlhahlobo e bonahalang

Tlhahlobo e bonoang ke ts'ebetso ea ho phahamisa thepa, ho hlahloba ponahalo ea sehlahisoa.

Wrinkles tiisong, makhulo a skewed meduthati, matheba a litšila a litšila, jj.

Tharollo e Tebileng

Tharollo e ikhethang le e phethahetseng e ka etsoa ho latela litlhoko tsa bareki.

Sethala sa Tima

Sethala sa Tima, se kopanyang R & D (ts'ebeliso e tlase haholo, litekanyetso tse tlase, mahlaseli a mangata, lialgorithms tsa mafolofolo, le boemo ba bohloeki bo phahameng.

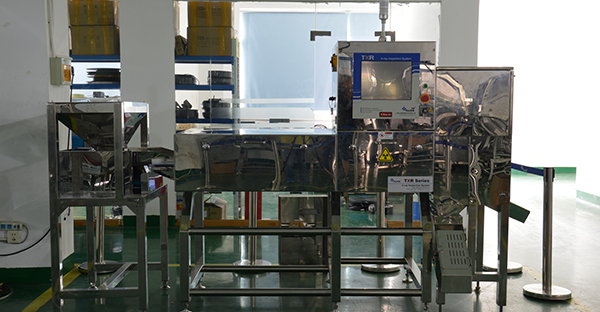

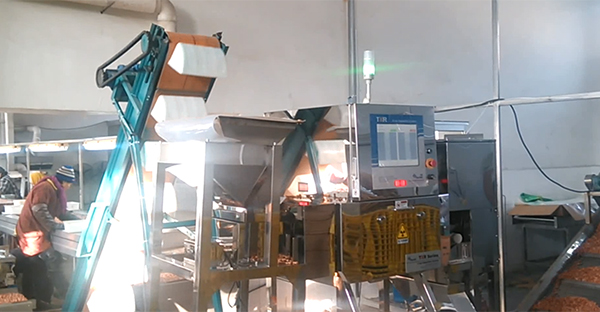

Tour ea fektheri

Packing