Culaysku wuxuu soo dejiyaa birta toosan

Theechik® - ka dhig nolosha xasilloonida iyo tayada

Culaysku wuxuu soo dejiyaa birta toosan

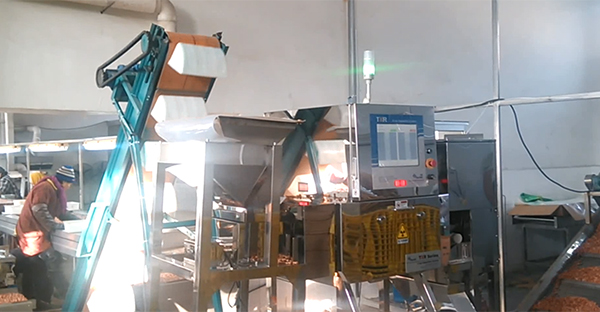

Techact cufnaanta birta ee birta ah Ka shaqeynta nidaamka ogaanshaha toosan, baarahaani wuxuu ku habboon yahay warshadaha u baahan ogaanshaha faddaraynta birta ee saxda ah inta lagu gudajiro gaadiidka badan ee culeyska.

Qalabka ayaa adeegsanaya tikniyoolajiyadda xasaasiga ah ee xasaasiga ah ee ogaanshaha in la garto xitaa walxaha birta ugu yar, ka hortagga faddaraynta iyo tayada wax soo saarka tayada. Ku habboon in la isticmaalo waaxaha sida ka baaraandegga cuntada, kiimikooyinka, iyo dawooyinka soosaarayaasha birta ee xiisaha leh way fududahay in lagu dhexgalo khadadka wax soo saarka ee jira oo loo dhiso inay wax ka qabato soosaarka soosaarka sare. Waxay ka caawisaa shirkadaha inay la kulmaan xeerarka adag ee badbaadada cuntada iyo xeerarka tayada, hubinta in alaabadoodu tahay birta-bilaash iyo nabadgelyo badbaado.

Codsiyada

Qalabka birta ee farsamada gacanta ee Techak waxaa lagu dabaqayaa dhowr warshado muhiim ah oo lagu ogaanayo wasakhooyinka birta ee agabka badan ee ku dhacaya:

- Ka shaqeynta cuntada:

Waxyaabaha budada ah: bur, sonkor, budo caano, iyo dhir udgoon.

Miraha iyo dalagyada: bariiska, qamadiga, saqafka, iyo galleyda.

Cunnooyinka fudud: miraha la qalajiyey, miraha qalalan, iyo abuurka.

Cabitaannada: Isku darka cabitaanka budada ah, cabitaannada, iyo xoojinta.

Macmacaan: shukulaato, nacnac, iyo waxyaabo kale oo macaan.

- Dawooyinka:

Waxyaabaha dawooyinka firfircoon (APIS):Budada iyo granulues loo isticmaalo wax soo saarka daroogada.

Kaabista:Fiitamiin iyo budada macdanta.

Kiimikooyinka iyo Bacriminta:

Kiimikooyinka budada ah: Kiimikooyinka loo isticmaalo howlaha wax soo saarka.

Bacriminta: Bacriminta granralar ee loo isticmaalo beeraha.

Cuntada xayawaanka:

Cuntada xayawaanka qalalan: Kible iyo waxyaabaha kale ee cuntada qalalan ee qalalan.

Caag iyo caag:

Granules caag ah: Qalabka cayriin ee wax soosaarka bacda ah.

Xerooyinka caagga ah: Granules loo isticmaalo ka baaraandegga caagga.

Waxsoosaarka beeraha:

Seeds: miraha kala duwan ee beeraha (tusaale, soybeans, abuurka gabbaldayaha).

Miraha iyo khudradda qalalan: Miraha qalalan sida sabiib, yaanyada la qalajiyey, iyo wax soo saarka beeraha kale ee badan.

Astaamaha

Nidaamka ogaanshaha toosan:

Naqshadeynta toosan waxay u oggolaaneysaa ogaanshaha sunta birta ee agabyada soo dhacaya, taasoo ka dhigeysa inay ku habboon tahay budada waaweyn, badarka, iyo waxyaabaha granralar.

Dareenka Sare:

Tiknolojiyadda badan ee soo noqnoqoshada badan ee tikniyoolajiyada waxay awood u siineysaa ogaanshaha qalloocinta ferraus, aan lahayn, iyo birta birta birta ah oo aan caadi ahayn oo dareenka galka ah, xitaa cabbir yar.

Nidaamka diidmada otomatiga ah:

Nidaamku wuxuu ku qalabeysan yahay qaababka diidmada otomatiga ah si looga saaro waxyaabaha wasakhaysan ee laga soo qaado khadka wax soo saarka iyada oo aan wax carqaladeynin qulqulka qalabka.

Dhismaha waarta:

Waxaa loogu talagalay in lagu iibiyo shaashadda-birta ee heerka-cuntada leh iyo waxyaabo tayo sare leh, hubinta waxqabadka muddada-dheer iyo isku halaynta jawiga dalbashada.

Is dhexgalka fudud:

Waxaa loogu talagalay in lagu daro is dhexgalka aan muuqan ee khadadka wax soo saarka ee jira, ee u baahan meeris yar oo loo habeeyo iyo wax ka badal hanaanka hadda jira.

Interface-u-habboon-saaxiibtinimo:

Wuxuu la imanayaa guddi xakameyn dareen leh oo u oggolaanaya hawl wadeenada inay si fudud u habeeyaan, kormeeraan, iyo isku hagaajinta dejinta waxqabadka ugu habboon.

Dejinta loo dhiso:

Heerarka dareenka ee la-hagaajinta iyo xudunta ogaanshaha ayaa u oggolaanaya nidaamka inuu ku fiicnaado noocyada alaabada gaarka ah iyo xaaladaha wax soo saarka.

U hogaansanaanta Heerarka Caalamiga ah:

Wuxuu la kulmaa qawaaniinta badbaadada cuntada ee caalamiga ah, oo ay ku jiraan HACCP, ISO 22000, iyo heerar kale oo la xiriira.

| Nooc | IMD-P | ||||

| Ka helidda Dhexroor (mm) | 75 | 100 | 150 | 200 | |

| Awoodda ogaanshaha T / H2 | 3 | 5 | 10 | 20 | |

| Yaliye Hab | Gaarti-taabto toos ah | ||||

| Cadaadis Baahansho | ≥0.5mpa | ||||

| Awoodda sahayda | AC220V (ikhtiyaari) | ||||

| Muhiimsan Wax | Bir bir ah (sus304) | ||||

| Xasaasiyadda ' Фd (mm) | Fe | 0.5 | 0.6 | 0.6 | 0.7 |

| Xash | 0.8 | 1 | 1.2 | 1.5 | |

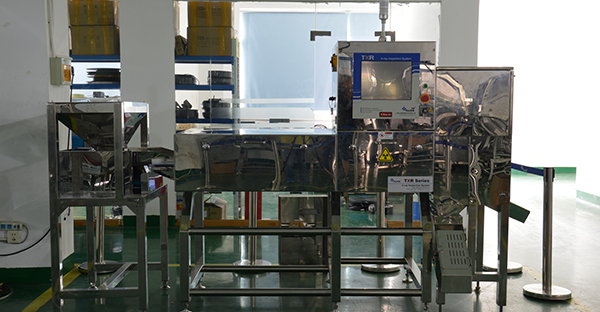

Booqashada warshadaha

Isku xiris

Hadafkayagu waa inaan hubinno aamin ah Theechik®.

Software-ka gudaha ku jira Qalabka raajada-tamarta ee jajabka lafaha si otomaatig ah u dhigma sawirrada sare iyo tamarta, iyo inay jiraan hay'adaha atomikada, oo ay jiraan hay'adaha shisheeye ee qaybaha kaladuwan si ay u kordhiyaan ogaanshaha Qiyaasta qashinka.