In the realm of food processing, the detection and removal of metal contaminants have long been facilitated by reliable metal detectors. However, the challenge remains: how can non-metal contaminants be efficiently identified and eliminated? Enter the Techik Food X-ray Inspection System, a cutting-edge solution designed to ensure the utmost safety and quality in the food industry.

Harnessing the power of X-ray technology, the Techik Food X-ray Inspection System goes beyond metal detection, enabling the identification of non-metal contaminants with exceptional precision. The underlying principle hinges on the density-based differences in matter. When subjected to X-ray inspection, substances of varying densities manifest distinct colors in the captured images. Leveraging this principle, the food X-ray inspection system excels at distinguishing between compliant products and foreign contaminants, which exhibit contrasting densities.

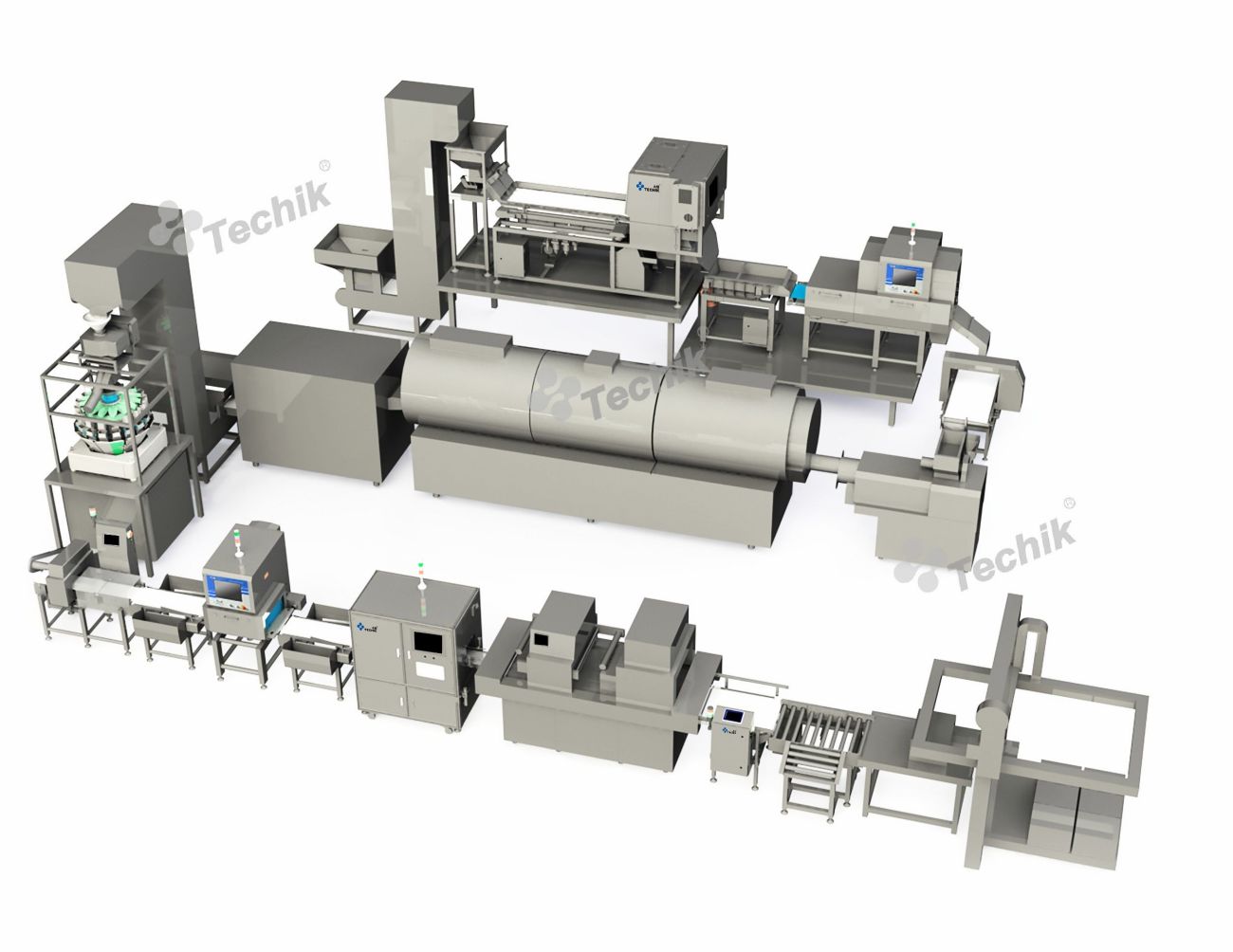

Techik’s relentless commitment to innovation has resulted in a diverse range of X-ray inspection systems tailored to specific sectors within the food industry. These systems have been meticulously crafted to address the unique challenges faced by different food sectors. From identifying glass and metal foreign objects around the bottoms and necks of cans, jars, and bottles, to detecting fragmented needles and bones in the meat industry, and even discerning fish bones in aquatic products – Techik’s X-ray inspection systems cover a spectrum of applications.

The technology’s capabilities extend to detecting thin sheet foreign bodies in frozen vegetables and ensuring the integrity of seals and stuffing in packaged snack foods. At the heart of these systems lies a fusion of advanced technologies – multi-spectral analysis, multi-energy spectrum detection, and multi-sensor integration. Techik’s commitment to enhancing every facet of inspection technology has led to the creation of X-ray inspection machines that cater to a diverse array of industries.

By effectively addressing pain points encountered by food enterprises and industries, Techik has successfully brought to market X-ray inspection systems that stand as beacons of safety, quality, and compliance. The safety of the food supply chain has never been more critical, and Techik’s Food X-ray Inspection Systems serve as an indomitable fortress against contaminants. With Techik, trust is not just earned; it’s reinforced through innovation and dedication to food safety.

The Techik Food X-ray Inspection System operates on the principle that different materials exhibit varying densities, which are visible through X-ray imaging. When food products pass through the inspection area, they are exposed to X-ray radiation. These rays are absorbed differently by materials, causing them to display distinct colors in the captured images. Techik’s advanced algorithms then analyze these images, identifying foreign contaminants based on their density and appearance. This allows for the precise differentiation between compliant products and potential contaminants, ensuring the highest levels of food safety and quality.

In summary, the Techik Food X-ray Inspection System embodies innovation, accuracy, and dedication to consumer welfare. By harnessing the power of X-ray technology, integrating advanced detection methods, and addressing diverse industry needs, Techik propels the food processing sector into a new era of uncompromising quality assurance.

Post time: Aug-16-2023