Intelligent Sorting Solution for the Macadamia Industry

Macadamia nuts are hailed as the “king of nuts” worldwide due to their rich nutritional value, high processing profitability, and broad market demand. The continual growth in the supply of macadamia nuts is inevitably raising the quality standards expected by consumers in response to the industry’s expansion, increasing the need for comprehensive solutions.

Techik has introduced an end-to-end, one-stop inspection and sorting solution tailored specifically for the macadamia nut industry. This solution is applicable to in-shell macadamia nuts, shelled nuts, nut fragments, and packaged products. It aids enterprises in enhancing both the quantity and quality of their products while addressing the challenges posed by industry expansion.

In-shell Macadamia Nuts & Macadamia Nut Kernel

The outer skin of macadamia nuts is greenish, and when the green skin is removed and dried, it results in the commonly found in-shell macadamia nuts in the market. Further processing of the macadamia nut kernels requires subsequent mechanical processes such as husking.

Macadamia Sorting Requirements:

- Detection and removal of shell fragments, metals, glass, and other foreign contaminants.

- Identification and removal of defective products, including mold, insect damage, red heart, and shrinkage.

Macadamia Sorting Solution Overview:

In-shell Macadamia Nuts & Macadamia Nut Kernel Sorting Solution -

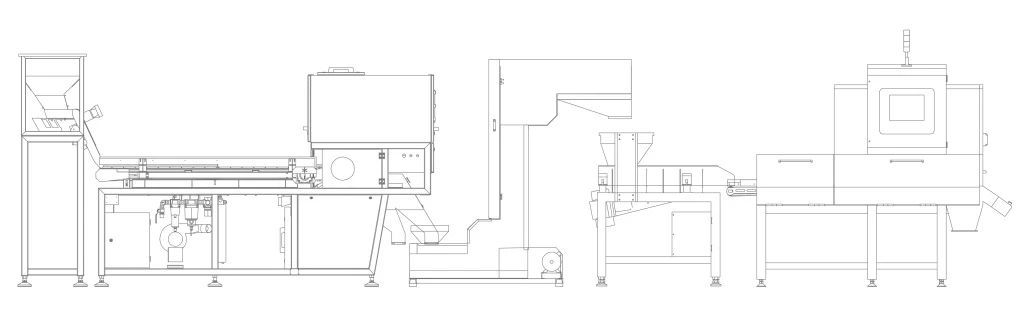

Quad-beam Belt-type Visual Sorting Machine + Combo X-ray Visual Inspection Machine

In-she ll Macadamia Nut Sorting:

ll Macadamia Nut Sorting:

The quad-beam belt-type visual sorting machine can perform a 360-degree comprehensive analysis of the appearance of macadamia nuts, replacing manual sorting by intelligently identifying shell fragments, branches, metals, and other impurities, as well as identifying unfit products with obvious shell damage or abnormal coloration.

Combo X-ray visual inspection machine, besides detecting metals and glass shards, can identify defects in in-shell macadamia nuts’ kernels, such as mold, shrinkage, hollowness, insect holes, and embedded impurities.

Macadamia Nut Kernel Sorting:

The quad-beam belt-type visual sorting machine, powered by AI deep learning algorithms and high-definition imaging, can identify unfit products such as red heart, flower heart, mold, germination, and shrinkage, along with shell fragments, metals, and other impurities.

Combo X-ray visual inspection machine can identify impurities and defects like insect damage, shrinkage, mold-related shrinkage, etc., in macadamia nut kernels.

Macadamia Nut Fragments:

Macadamia nut fragments are widely used food ingredients in pastries, candies, chocolates, ice cream, bubble tea, and other food and beverage products. In recent years, processing companies have increasingly prioritized the quality of nut fragments to avoid complaints regarding issues such as mold and foreign materials.

Sorting Requirements:

- Detection and removal of slight foreign materials like hair, as well as metals, glass, and other impurities.

- Sorting of defective products affected by mold, abnormal colors, etc.

Sorting Solution Overview:

Macadamia Nut Fragments Sorting Solution –

Waterproof Ultra-High-Definition Belt-type Visual Sorting Machine + Dual-energy Bulk X-ray Inspection Machine

The waterproof ultra-high-definition belt-type visual sorting machine not only identifies abnormalities such as color, shape, shell fragments, and metal particles but also replaces multiple manual workers by effectively identifying slight and small foreign objects like hair, fine strings, and insect remains.

The dual-energy bulk X-ray inspection machine can perform dual recognition of shape and material, identifying impurities such as metal, ceramics, glass, PVC plastic, etc.

Packaged Macadamia Nut Products:

Macadamia nuts can be processed into various products, such as mixed nut snacks, nut chocolates, nut pastries, etc.

Sorting Requirements:

- Detection and removal of impurities like metal, glass, stones, etc.

- Detection of product defects, overweight/underweight products.

- Quality checks on packaging aspects such as sealing, for example, ensuring that leisure snacks containing macadamia nuts have properly sealed packaging without foreign materials.

The whole chain finished product inspection solution comprises intelligent visual inspection systems, weight inspection systems, intelligent X-ray inspection systems, allowing customization based on customer inspection needs, covering various quality issues like foreign objects, product defects, seal defects, non-compliant weights, and more.

For issues in the macadamia nut industry such as mold, insect damage, shrinkage, red heart, flower heart, and foreign hair, Techik’s intelligent visual sorting machines, intelligent X-ray visual integrated machines, and intelligent bulk food X-ray inspection machines are tailored to cover various inspection and sorting needs in the initial and subsequent processing stages of macadamia nuts and their derived products. These solutions have been rigorously tested and widely acclaimed by industry clients in the market.

Post time: Nov-24-2023