Pipeline Metal Detector for Sauce and Liquid

Thechik® — MAKE LIFE SECURE AND QUALITY

Pipeline Metal Detector for Sauce and Liquid

Techik Ultra-High-Definition Intelligent Belt Visual Color Sorter is a versatile solution designed to sort an extensive range of products, including frozen vegetables, fresh and dried fruits and vegetables, dehydrated shallots and garlic, carrots, peanuts, tea leaves, and peppers. Beyond traditional AI-based color and shape sorting, this advanced sorter effectively replaces manual inspection by detecting minor foreign contaminants, such as hair, feathers, strings, and insect fragments, with remarkable accuracy, ensuring high sorting rates, high output, and minimal raw material waste.

Optimized for dynamic and complex processing environments, Techik Ultra-High-Definition Intelligent Belt Visual Color Sorter features an IP65 protection rating and is engineered for stringent hygiene standards, making it suitable for various sorting needs. These include fresh, frozen, and freeze-dried fruit and vegetable products, as well as processing stages in food preparation, frying, and baking. Its multispectral detection capabilities cover color, shape, appearance, and material composition, ensuring comprehensive quality control across all aspects of production.

Equipped with an ultra-high-definition camera, the optical sorter can achieve precise identification of tiny impurities like hair and strings. The proprietary AI algorithm and high-speed rejection system deliver high cleanliness, low carry-out rates, and substantial throughput.

With its IP65-rated protection, this color sorter operates effectively in high-moisture and dusty environments, adapting seamlessly to diverse sorting applications in frying, baking, and more. Designed for easy maintenance, it includes a quick-disassembly structure that simplifies cleaning, ensuring a consistently sanitary production process.

Applications

Techik's Pipeline Metal Detector for Sauce and Liquid is ideal for a variety of applications where liquid and semi-liquid food products are processed. It helps food manufacturers meet the highest safety standards while preventing metal contamination in their products:

Sauces:

Detects metal contaminants in a variety of sauces such as ketchup, mayonnaise, hot sauce, BBQ sauce, salad dressing, and pasta sauces.

Soups and Broths:

Ensures that soups, broths, and ready-to-serve liquid meals are free from metal particles during production and packaging.

Condiments:

Effective in detecting metals in condiments like mustard, soy sauce, vinaigrettes, and other liquid condiments used in the food industry.

Paste and Purees:

Detects metal contaminants in paste-like products, such as tomato paste, fruit purees, and other thick or semi-thick pastes used in food processing.

Dips and Spreads:

Used to detect metals in products like hummus, salsa, guacamole, and other spreadable products during manufacturing.

Beverages:

Detects metal contaminants in liquid beverages such as fruit juices, energy drinks, soft drinks, and dairy beverages during the bottling and packaging process.

Features

High Sensitivity Detection:

Detects ferrous, non-ferrous, and stainless steel metals, providing high sensitivity even for very small metal particles, which is critical for ensuring contamination-free sauces and liquid products.

Automatic Rejection System:

Features an integrated automatic rejection system that efficiently removes contaminated products from the production line, ensuring that only safe, metal-free products reach the packaging stage.

Flow-Through Design:

Optimized for the flow-through nature of liquid and semi-liquid products, allowing for easy integration into production lines where sauces, soups, dressings, and other viscous products are processed.

Durable Construction:

Built with food-grade stainless steel and materials that are resistant to corrosion, ensuring long-lasting performance in liquid food production environments.

Easy Integration:

Designed for simple installation into existing sauce production lines, minimizing the need for major adjustments or downtime during setup.

User-Friendly Interface:

Comes with an intuitive control panel, allowing for easy adjustments to sensitivity levels, detection parameters, and operational monitoring.

Compliance with Global Standards:

Meets essential food safety and quality standards such as HACCP, ISO 22000, and others, ensuring that your products comply with international regulations.

Technical Advantages

High Sensitivity and Precision:

Uses advanced multi-spectrum techn ology for high-precision metal detection, identifying even the smallest metal fragments in sauces and other viscous products.

Efficient and Automatic Contamination Removal:

Equipped with a quick and reliable automatic rejection system that removes contaminated products from the production line without disrupting the process.

Optimized for Liquid and Semi-Liquid Products:

Specifically designed for the detection of metals in liquids and semi-liquids, handling both thick and thin materials with ease, ensuring product integrity during processing.

Easy-to-Use and Maintain:

With a user-friendly interface, operators can easily monitor, configure, and adjust detection parameters, ensuring ease of operation and minimizing downtime for maintenance.

Built for Harsh Environments:

Constructed with food-grade stainless steel and materials resistant to corrosion, the detector is built to withstand the moisture and chemical exposure typical in food processing environments.

Global Compliance:

Meets international food safety and quality standards (HACCP, ISO 22000, FDA, etc.), ensuring regulatory compliance and safe food production.

Seamless Integration:

Can be easily integrated into existing sauce production lines without major modification, offering a cost-effective solution that improves operational efficiency and ensures product safety.

| Model | IMD- ⅡS-P75 |

| Tube inner diameter (mm) | 75 |

| Detection sensitivity (Fe ball) | 0.5 |

| Detection sensitivity (SUS304 ball) | 0.8 |

| Maximum load (KG) | / |

| Maximum Power | AC110V/220V |

| Weight (KG) | 80 |

| Product numbers | 60/100 |

| Tested products form | Bulk, powder, granule |

| Air source requirements | 0.5MPA |

| Rejecter | Flap rejecter |

| Alarm method | Alarm rejecter |

| Tube material | PP |

| Display method | LED LCD/FDM touch screen |

| Operation method | Key input/touch screen |

| IP level | IP54/IP65 |

| Included interface | USB port, Ethernet port |

| Display language | Chinese and English (other languages are optional) |

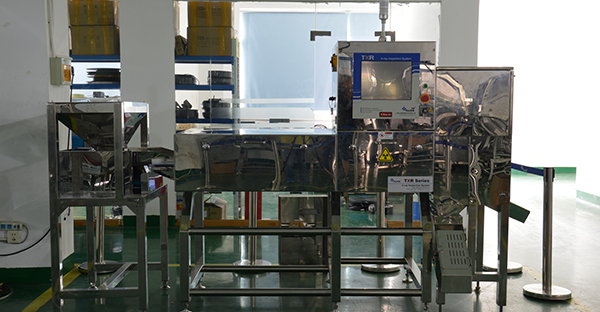

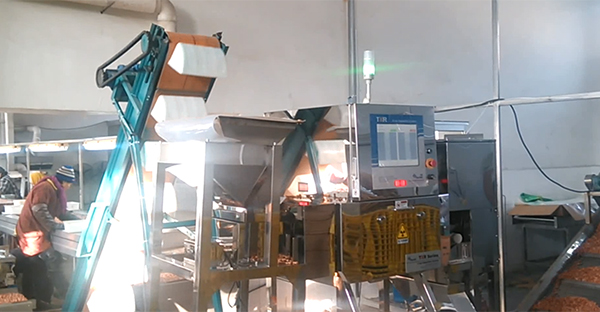

Factory Tour

Packing

Our Goal Is To Ensure Safe With Thechik®.

The software inside Techik Dual-energy X-ray Equipment for Bone Fragment automatically compares the high and low energy images, and analyzes, through the hierarchical algorithm, whether there are atomic number differences, and detects the foreign bodies of different components to increase the detection rate of debris.