Gravity Fall Vertical Metal Detector

Thechik® — MAKE LIFE SECURE AND QUALITY

Gravity Fall Vertical Metal Detector

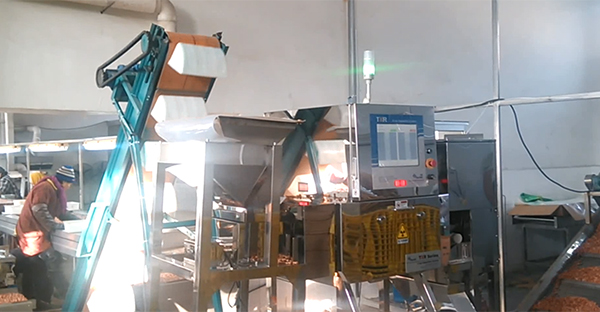

Techik Gravity Fall Metal Detector (Vertical Metal Detector) is an advanced solution designed to detect ferrous, non-ferrous, and stainless steel contaminants in free-falling bulk products, such as powders, granules, and small particles. Operating on a vertical detection system, this detector is suitable for industries that require accurate and reliable metal contamination detection during the transport of bulk materials via gravity.

The device uses high-sensitivity detection technology to identify even the smallest metal particles, preventing contamination and safeguarding product quality. Ideal for use in sectors such as food processing, chemicals, and pharmaceuticals, the Gravity Fall Metal Detector is easy to integrate into existing production lines and is built to handle high-throughput production environments. It helps companies meet strict food safety and quality regulations, ensuring that their products are metal-free and safe for consumers.

Applications

Techik’s Gravity Fall Metal Detector is applied in several key industries for detecting metal contaminants in free-falling bulk materials:

- Food Processing:

Powdered Ingredients: Flour, sugar, milk powder, and spices.

Grains and Cereals: Rice, wheat, oats, and corn.

Snack Foods: Nuts, dried fruits, and seeds.

Beverages: Powdered drink mixes, juices, and concentrates.

Confectionery: Chocolate, candies, and other bulk confectionery items.

- Pharmaceuticals:

Active Pharmaceutical Ingredients (APIs): Powders and granules used in drug manufacturing.

Supplements: Vitamin and mineral powders.

Chemicals and Fertilizers:

Powdered Chemicals: Chemicals used in manufacturing processes.

Fertilizers: Granular fertilizers used in agriculture.

Pet Food:

Dry Pet Food: Kibble and other dry pet food products.

Plastic and Rubber:

Plastic Granules: Raw material for plastic manufacturing.

Rubber Compounds: Granules used in rubber processing.

Agricultural Products:

Seeds: Various agricultural seeds (e.g., soybeans, sunflower seeds).

Dry Fruits and Vegetables: Dried fruits like raisins, dried tomatoes, and other bulk agricultural produce.

Features

Vertical Detection System:

The vertical design allows for the detection of metal contaminants in free-falling materials, making it ideal for bulk powders, grains, and granular products.

High Sensitivity:

Advanced multi-frequency technology enables detection of ferrous, non-ferrous, and stainless steel metals with exceptional sensitivity, even at small particle sizes.

Automatic Rejection System:

The system is equipped with an automatic rejection mechanism to remove contaminated products from the production line without interrupting the flow of materials.

Durable Construction:

Designed with food-grade stainless steel and high-quality materials, ensuring long-term performance and reliability in demanding environments.

Easy Integration:

Designed for seamless integration into existing production lines, requiring minimal setup and modification to the current process.

User-Friendly Interface:

Comes with an intuitive control panel that allows operators to easily configure, monitor, and adjust settings for optimal performance.

Customizable Settings:

Adjustable sensitivity levels and detection parameters allow the system to be fine-tuned for specific product types and production conditions.

Compliance with Global Standards:

Meets international food safety regulations, including HACCP, ISO 22000, and other relevant standards.

| MODEL | IMD-P | ||||

| Detection Diameter (mm) | 75 | 100 | 150 | 200 | |

| Detection Capacity t/h2 | 3 | 5 | 10 | 20 | |

| Rejecter Mode | Automatic flap rejecter | ||||

| Pressure Requirement | ≥0.5Mpa | ||||

| Power Supply | AC220V (Optional) | ||||

| Main Material | Stainless Steel (SUS304) | ||||

| Sensitivity' Фd(mm) | Fe | 0.5 | 0.6 | 0.6 | 0.7 |

| SUS | 0.8 | 1 | 1.2 | 1.5 | |

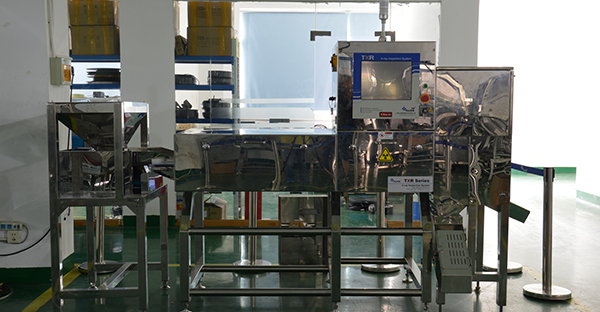

Factory Tour

Packing

Our Goal Is To Ensure Safe With Thechik®.

The software inside Techik Dual-energy X-ray Equipment for Bone Fragment automatically compares the high and low energy images, and analyzes, through the hierarchical algorithm, whether there are atomic number differences, and detects the foreign bodies of different components to increase the detection rate of debris.