Food Meat Frozen Vege Fruit X-ray Inspection System

*Food Meat Frozen Vege Fruit X-ray Inspection System Introduction:

Techik Food Meat Frozen Vege Fruit X-ray Inspection Systems are widely used in meat, frozen vegetables and fruits, bulk products industries.

In meat industry, the hard bone can be easily detected; via machine auto learning, the X-ray inspection machine can conduct fat content inspection of meat. The meat dual-energy X-ray inspection machine can analyze different element of products, even of the products are overlapped, it can detect the foreign body. The machine's performance can achieve its best when the meat is inspected before packing.

In bulk products industry, take peanut as an example. Under the condition of capacity at 1.5 ton per hour, 0.7mm glass can be successfully detected.

For granular products (Chips, Frozen Vegetables, Nuts, etc.), non-organic materials are not affected by the uniformity of the product itself, greatly improving the stability of detection.

*Advantages of Food Meat Frozen Vege Fruit X-ray Inspection System

1. Due to the overlapping parts of products when multiple packets pass continuously, false alarms are prone to occur. In this case, Dual Energy X-ray Inspection System can largely ignore the influence of gray scale changes caused by this overlap and achieve better sensitivity and stable detection.

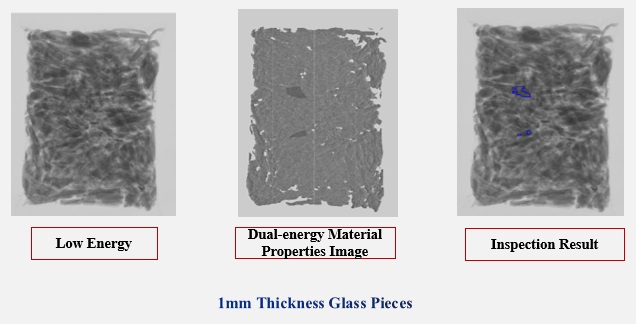

2. Better performance for low density contaminants especially thin Glass pieces

*Working Principle of Food Meat Frozen Vege Fruit X-ray Inspection System

The dual-energy X-ray inspection system gets both the low-energy and high-energy data. After PC calculation, software automatically compares the high and low energy images. The higher resolution result will increase the detection rate of foreign matter.

*Test Image

*Related Products

For meat industry, Techik product matrix includes Bone fragments inspection TXR-CB series, Oil Leakage Inspection TXR series and etc.

*Packing

*Customer applications