1.Meat product introduction:

Meat product refers to raw ,fresh meat in open mode or packed in foil or package. And also the processed meat product.

2.Our application in meat sector

1).Raw meat

Before-Packing (meat in slice)

Raw material inspection for needles or other metal.

Standard X-ray inspection system is widely used for metal or bone detecting in slice of meat.

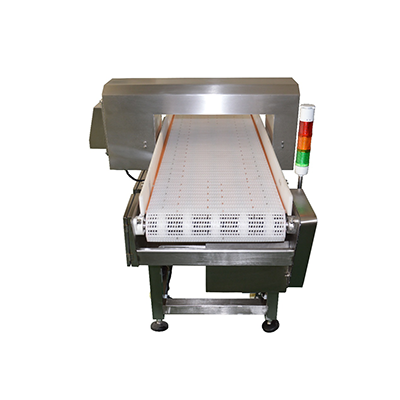

Metal detector is used for metal detecting in slice of meat.

Weigh-sorting system is used for weigh sorting for meat in different range.

After-Packing (meat in the condition of frozen or fresh, packed in carton)

Standard X-ray inspection system is widely used for metal or bone detecting packed in carton. Sensitivity is better than metal detector .(The sensitivity is not related to condition of meat )

Metal detector is widely used for metal detecting in packed. The sensitivity is better in frozen than in fresh.

Processed product:

Before-Packing (meat in sauce)

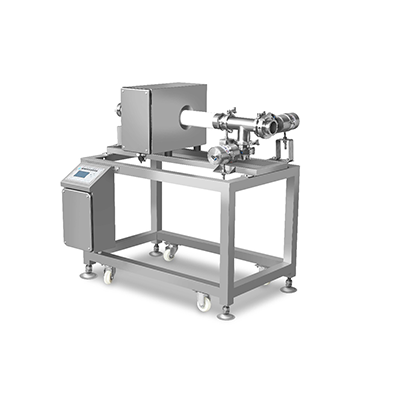

Pipe metal detector is used for processed meat product . Sensitivity is depending on speed and pipe dimension.

Pipe X-ray inspection system is used for processed meat product . especially for metal and other hard object.

After-Packing(sausage)

Standard X-ray inspection system is widely used for foreign part in sausage.

Weigh-checking system is used for weigh of meat in different range.

2).Poultry

Raw poultry:

Standard X-ray inspection system is widely used for metal or hard bone detecting in poultry

Metal detector is used for metal detecting in slice of frozen poultry. For fresh poultry ,X-ray machine is better due to the product effect.

Weigh-sorting system is used for weigh sorting for poultry in different range.

Processed product

Standard X-ray inspection system is widely used for metal or hard bone detecting in processed product

Metal detector is used for metal detecting in slice of frozen product. For fresh product ,X-ray machine is better due to the product effect.

Post time: Apr-27-2020